Safety is a major concern in most industrial setups, especially where workers have to use face shields or goggles.

It is for this reason that companies invest in technologies such as anti-scratch coating for plastics that can improve performance and reliability of these products.

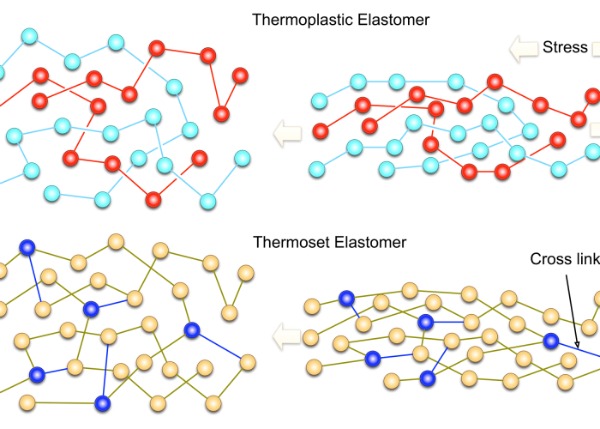

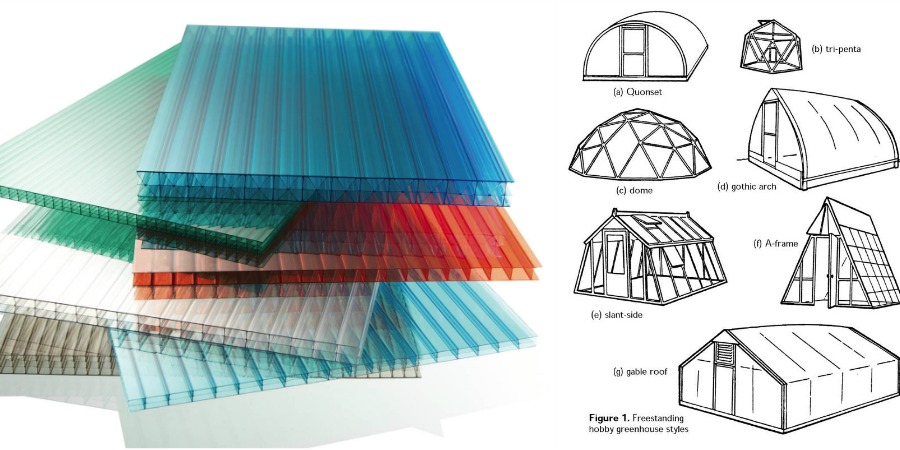

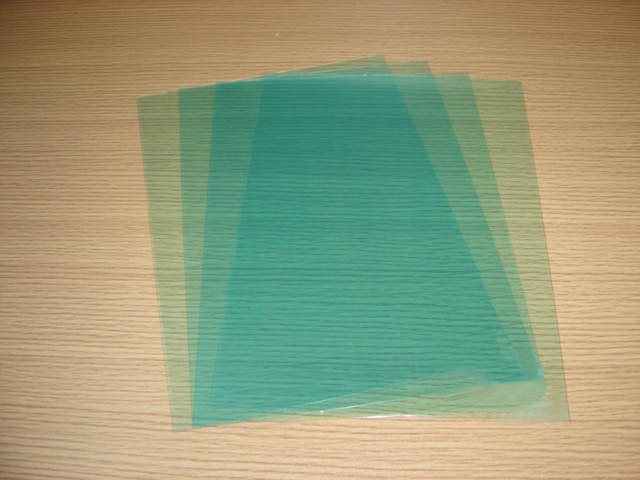

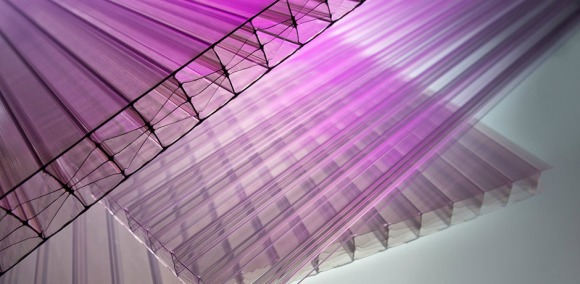

Polycarbonate is a versatile and reliable polymer. This is due to its superior physical and chemical properties.

However, it is not 100% perfect. At times, you need to add other products to make it a perfect choice for a specific application.

There are a number of steps you have to follow to achieve the required degree of safety.

1.The Plastic Surface Should Have Anti-scratch Coating

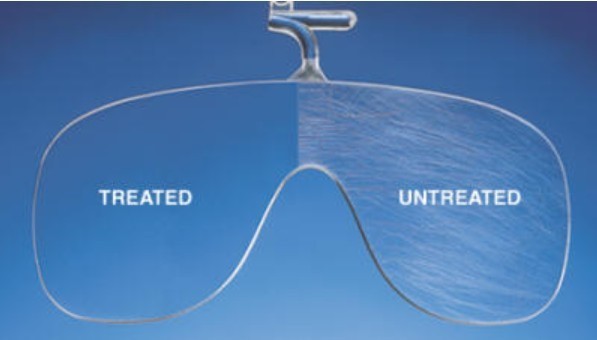

Scratches or marks on safety goggles and face shields impair vision. As a result, one has to strain to see through these safety equipment.

This makes it prudent to find a way of eliminating all scratches without interfering with the desired qualities of the safety gears. Remember, eye strain can be devastating. As a matter of fact, you may not be able to focus on the work at hand.

In short, you have no option but, to go for safety gears with anti-scratch coating. It is the only sure way of improving performance and reliability of this equipment.

An anti-scratch coating for plastics are chemical substrates that bind on polycarbonate or acrylic sheet. The process involves dip or flow coating. After which, the coating substrate is cured through UV or thermal energy.

With this, the anti-scratch coating firmly attaches on the polycarbonate or acrylic surface. This creates a surface that is wear resistance.

Normally, this film is so thin that it does not interfere with the degree of light transmission. It is 99.9% transparent. This is based on turbidimeter test results. Of course, this also complies with the ASTM test standards.

Of course, with all these, goggles or face shield will guarantee safety at all times.

2.Use Appropriate Coating That Suit Your Working Condition

There are different types of plastic coating formulated for different working conditions. There are different environmental conditions that may affects our eyes. Therefore, we need to be cautious all the time.

These environmental conditions may include:

- UV radiation

- Abrasive substances

- Reflection

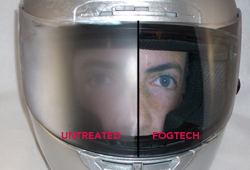

- Fog

This implies, any safety gear should filter or prevent all these to consider it safe. Of course, there is no single technology that can eliminate all these.

In most cases, you will have to use either one or two, depending on your environmental condition.

The good news is, you can use anti-scratch coating with all these technologies. That is, you can consolidate it with anti-glare, anti-graffiti, UV and abrasion resistant coating.

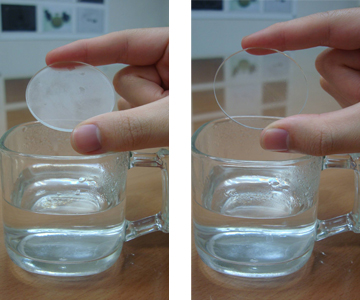

However, when it comes to anti-fog coating, the mode of application is slightly different. That is, you will apply anti-scratch and anti-fog coatings on opposite sides of the plastic. Therefore, you will end up with anti-fog coating on one side while anti-scratch coating on the other.

Note: For anti fog solutions,here is a ultimate guide of anti fog solutions which will solve all fogging problems.

In short, using more than one plastic coating technology will protect you from any environmental hazards.

3.Go for High Quality Anti-scratch Coating for Plastics

Quality is an important aspect when choosing an anti-scratch coating for any application. They are the only substrates will stick permanently on the polycarbonate or acrylic surface.

Any plastic that fades or ceases to be effective after a short period of time will expose you to unnecessary risks. That is, the surface may begin to have scratches, thus, you will not see clearly. As a result, your safety will be compromised.

There is one way to solve this problem:

Buy all anti-scratch coating for plastics from reputable companies. Such companies adhere to the approved manufacturing standards. All their anti-scratch products are subjected to all the necessary tests for anti-scratch coating. These tests include:

- Taber test

- Steel wool test

- Eraser test

- Tumble test

For a fact, you may not be able to conduct these tests successfully on your own. This is because some require special equipment. It is for this reason that you need to go for reputable companies.

4.Conduct Regular Tests and Inspection on Safety Gears

Anti-scratch coating for plastics are designed to last for years. However, due to unavoidable circumstances, they may cease to be effective. Under such circumstances, the surface could be susceptible to scratches.

Of course, such situations are covered in the product warranty. However, to be safe, you should be able to identify such circumstances in good time to avoid unnecessary accidents.

You can only achieve this if you conduct regular inspections on all safety equipment with anti-fog coating. So, regular inspection is also an important procedure when you want to ensure safety at the workplace.

5.Every Worker Must Wear a Safety Equipment with Anti-scratch Coating

There is no excuse why one should not wear a safety equipment with the right plastic coating. As mentioned earlier, anti-scratch coating can be consolidated with other technologies to guarantee safety.

Remember, there is the Occupational Safety and Health Act that stipulate what is expected of every worker. You must uphold these regulations at whatever cost.

Conclusion

It is the responsibility of every individual to ensure they have the right safety equipment. That is, one with anti-scratch coating for plastics plus additional technologies that guarantee safety.

The

The